| Item Name | Threaded concentric reducer |

| Use | Engineering construction( fire protection,pipe transportation,water pipe, cable protection, mine industry,etc.) |

| Material | Ductile cast iron conforming to ASTM A-536, Grade 65-45-12 |

| Cerification | ISO 9001:2008,FM,UL,CCC and CE approved |

| Technology | Casting |

| Color | Many colors available for choice(Blue,Red,Silver) |

| Surface Treatment | Epoxy powder coating (Red color- RAL3000; Orange)Optional: Galvanized (Zinc Plated, HDG Or Dip painted) |

| Size | 1"-12" |

| Working Pressure | 300PSI |

| Connect End Type | Grooved end ,Thread end |

| Delivery | 15 days |

| Packing Details | Cartons or Cartons on Pallet |

| Payment | By T/T,L/C |

| OEM | YES |

| Factory | YES |

| Brand Name | Plato |

| Type of production | 1) Rigid Coupling,Flexible Coupling, Reducing Flexible Coupling |

| 2) Long Radius and Short Radius Elbow (90°/45°/22.5°/11.25°) | |

| 3) Equal Tee, Grooved Reducing Tee, Grooved Reduing Tee(Threaded outlet) | |

| 4) Grooved Mechanical Tee,Grooved Mechanical Cross | |

| 5) Equal Cross, Grooved Reducing Cross | |

| 6) Grooved Reducer, Threaded Reducer | |

| 7) Adapter Flange, Grooved Split Flange | |

| 8) Cap,End Cap |

| Nominal Size | Pipe OD | Dimensions | Working Pressure | Certificate |

| Unit( mm/inch) | ||||

| Unit( mm/inch) | Unit( mm/inch) | L | Unit(Psi/Mpa) | |

| 50*15 2*1/2 | 60.3*21.3 2.375*0.825 | 64 2.520 | 350 2.5 | FM UL |

| 50*20 2*3/4 | 60.3*26.9 2.375*1.05 | 64 2.520 | 350 2.5 | FM UL |

| 50*25 2*1 | 60.3*33.7 2.375*1.315 | 64 2.520 | 350 2.5 | FM UL |

| 50*32 2*11/4 | 60.3*42.4 2.375*1.660 | 64 2.520 | 350 2.5 | FM UL |

| 50*40 2*11/2 | 60.3*48.3 2.375*1.900 | 64 2.520 | 350 2.5 | FM UL |

| 65*15 21/2*1/2 | 73.0*21.3 2.875*0.825 | 64 2.520 | 350 2.5 | FM UL |

| 65*20 21/2*3/4 | 73.0*26.9 2.875*1.050 | 64 2.520 | 350 2.5 | FM UL |

| 65*25 21/2*1 | 73*33.7 2.875*1.315 | 64 2.520 | 350 2.5 | FM UL |

| 65*32 21/2*11/4 | 73*42.4 2.875*1.660 | 64 2.520 | 350 2.5 | FM UL |

| 65*40 21/2*11/2 | 73*48.3 2.875*1.900 | 64 2.520 | 350 2.5 | FM UL |

| 65*50 21/2*2 | 73*60.3 2.875*2.375 | 64 2.520 | 350 2.5 | FM UL |

| 65*15 3OD*1/2 | 76.1*21.3 3.000*0.825 | 64 2.520 | 350 2.5 | FM UL |

| 65*20 3OD*3/4 | 76.1*26.9 3.000*1.050 | 64 2.520 | 350 2.5 | FM UL |

| 65*25 3OD*1 | 76.1*33.7 3.00*1.315 | 64 2.520 | 350 2.5 | FM UL |

| 65*32 3OD*11/4 | 76.1*42.4 3.000*1.660 | 64 2.520 | 350 2.5 | FM UL |

| 65*40 3OD*11/2 | 76.1*48.3 3.000*1.900 | 64 2.520 | 350 2.5 | FM UL |

| 65*50 3OD*2 | 76.1*60.3 3.000*2.375 | 64 2.520 | 350 2.5 | FM UL |

| 80*15 3*1/2 | 88.9*21.3 3.500*0.825 | 64 2.520 | 350 2.5 | FM UL |

| 80*20 3*3/4 | 88.9*26.9 3.500*1.050 | 64 2.520 | 350 2.5 | FM UL |

| 80*25 3*1 | 88.9*30.7 3.500*1.315 | 64 2.520 | 350 2.5 | FM UL |

| 80*32 3*11/4 | 88.9*42.4 3.500*1.660 | 64 2.520 | 350 2.5 | FM UL |

| 80*40 3*11/2 | 88.9*48.3 3.500*2.375 | 64 2.520 | 350 2.5 | FM UL |

| 80*50 3*2 | 88.9*60.3 3.500*2.875 | 64 2.520 | 350 2.5 | FM UL |

| 80*65 3*21/2 | 88.9*73 3.500*2.875 | 64 2.520 | 350 2.5 | FM UL |

| 80*65 3*3OD | 88.9*76.1 3.500*3.000 | 64 2.520 | 350 2.5 | FM UL |

| 100*25 41/4OD*1 | 108.0*33.7 4.250*1.315 | 76 2.992 | 350 2.5 | FM UL |

| 100*32 41/4OD*11/4 | 108.0*42.4 4.250*1.660 | 76 2.992 | 350 2.5 | FM UL |

| 100*40 41/4OD*11/2 | 108.0*48.3 2.375*1.900 | 76 2.992 | 350 2.5 | FM UL |

| 100*50 41/4OD*2 | 108.0*60.3 4.250*2.375 | 76 2.992 | 350 2.5 | FM UL |

| 100*65 41/4OD*21/2 | 108.0*73.0 4.250*2.875 | 76 2.992 | 350 2.5 | FM UL |

| 100*65 41/4OD*3OD | 108.0*76.1 4.250*3.000 | 76 2.992 | 350 2.5 | FM UL |

| 100*80 41/4OD*3 | 108.0*88.9 4.250*3.500 | 76 2.992 | 350 2.5 | FM UL |

| 100*15 4*1/2 | 114.3*21.3 4.500*0.825 | 76 2.992 | 350 2.5 | FM UL |

| 100*20 4*3/4 | 114.3*26.9 4.500*1.050 | 76 2.992 | 350 2.5 | FM UL |

| 100*25 4*1 | 114.3*33.7 4.500*1.315 | 76 2.992 | 350 2.5 | FM UL |

| 100*32 4*11/4 | 114.3*42.4 4.500*1.660 | 76 2.992 | 350 2.5 | FM UL |

| 100*40 4*11/2 | 114.3*48.3 4.500*1.900 | 76 2.992 | 350 2.5 | FM UL |

| 100*50 4*2 | 114.3*60.3 4.500*2.375 | 76 2.992 | 350 2.5 | FM UL |

| 100*65 4*21/2 | 114.3*73.0 4.500*2.875 | 76 2.992 | 350 2.5 | FM UL |

| 100*65 4*3OD | 114.3*76.1 4.500*3.000 | 76 2.992 | 350 2.5 | FM UL |

| 100*80 4*3 | 114.3*88.9 4.500*3.500 | 76 2.992 | 350 2.5 | FM UL |

| 125*15 51/4OD*1/2 | 133.0*21.3 5.250*0.825 | 89 3.504 | 350 2.5 | FM UL |

| 125*20 51/4OD*3/4 | 133.0*26.9 5.250*1.050 | 89 3.504 | 350 2.5 | FM UL |

| 125*25 51/4OD*1 | 133.0*33.7 5.250*1.660 | 89 3.504 | 350 2.5 | FM UL |

| 125*32 51/4OD*11/4 | 133.0*42.4 5.250*1.660 | 89 3.504 | 350 2.5 | FM UL |

| 125*40 51/4OD*11/2 | 133.0*48.3 5.250*1.900 | 89 3.504 | 350 2.5 | FM UL |

| 125*50 51/4OD*2 | 133.0*60.3 5.250*2.375 | 89 3.504 | 350 2.5 | FM UL |

| 125*65 51/4OD*21/2 | 133.0*73.0 5.250*2.875 | 89 3.504 | 350 2.5 | FM UL |

| 125*65 51/4OD*3OD | 133.0*76.1 5.250*3.000 | 89 3.504 | 350 2.5 | FM UL |

| 125*80 51/4OD*3 | 133.0*88.9 5.250*3.500 | 89 3.504 | 350 2.5 | FM UL |

| 125*100 51/2OD*4 | 133.0*114.3 5.250*4.500 | 89 3.504 | 350 2.5 | FM UL |

| 125*15 51/2OD*1/2 | 139.7*21.3 5.500*0.825 | 89 3.504 | 350 2.5 | FM UL |

| 125*20 51/2OD*3/4 | 139.7*26.9 5.500*1.050 | 89 3.504 | 350 2.5 | FM UL |

| 125*25 51/2OD*1 | 139.7*33.7 5.563*1.315 | 89 3.504 | 350 2.5 | FM UL |

| 125*32 51/2OD*11/4 | 139.7*42.4 5.563*1.660 | 89 3.504 | 350 2.5 | FM UL |

| 125*40 51/2OD*11/2 | 139.7*48.3 5.563*1.900 | 89 3.504 | 350 2.5 | FM UL |

| 125*50 51/2OD*2 | 139.7*60.3 5.563*2.375 | 89 3.504 | 350 2.5 | FM UL |

| 125*65 51/2OD*21/2 | 139.7*73.0 5.563*2.875 | 89 3.504 | 350 2.5 | FM UL |

| 125*65 51/2OD*3OD | 139.7*76.1 5.563*3.000 | 89 3.504 | 350 2.5 | FM UL |

| 125*80 51/2OD*3 | 139.7*88.9 5.563*3.500 | 89 3.504 | 350 2.5 | FM UL |

| 125*100 51/2OD*4 | 139.7*114.3 5.563*4.500 | 89 3.504 | 350 2.5 | FM UL |

| 150*15 61/4OD*1/2 | 159.0*21.3 6.250*0.825 | 102 4.016 | 350 2.5 | FM UL |

| 150*20 61/4OD*3/4 | 159.0*26.9 6.250*1.050 | 102 4.016 | 350 2.5 | FM UL |

| 150*25 61/4OD*1 | 159.0*33.7 6.625*1.315 | 102 4.016 | 350 2.5 | FM UL |

| 150*32 61/4OD*11/4 | 159.0*42.4 6.625*1.660 | 102 4.016 | 350 2.5 | FM UL |

| 150*40 61/4OD*11/2 | 159.0*48.3 6.625*1.900 | 102 4.016 | 350 2.5 | FM UL |

| 150*50 61/4OD*2 | 159.0*60.3 6.625*2.375 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 61/4OD*21/2 | 159.0*73.0 6.625*2.875 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 61/4OD*3OD | 159.0*76.1 6.625*3.000 | 102 4.016 | 350 2.5 | FM UL |

| 150*80 61/4OD*3 | 159.0*88.9 6.625*3.500 | 102 4.016 | 350 2.5 | FM UL |

| 150*100 61/4OD*4 | 159.0*114.3 6.625*4.500 | 102 4.016 | 350 2.5 | FM UL |

| 150*15 61/2OD*1/2 | 165.1*21.3 6.625*0.825 | 102 4.016 | 350 2.5 | FM UL |

| 150*20 61/2OD*3/4 | 165.1*26.9 6.625*1.315 | 102 4.016 | 350 2.5 | FM UL |

| 150*25 61/2OD*1 | 165.1*33.7 6.500*1.315 | 102 4.016 | 350 2.5 | FM UL |

| 150*32 61/2OD*11/4 | 165.1*42.4 6.500*1.660 | 102 4.016 | 350 2.5 | FM UL |

| 150*40 61/2OD*11/2 | 165.1*48.3 6.500*1.900 | 102 4.016 | 350 2.5 | FM UL |

| 150*50 61/2OD*2 | 165.1*60.3 6.500*2.375 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 61/2OD*21/2 | 165.1*73 6.500*2.875 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 61/2OD*3OD | 165.1*76.1 6.500*3.000 | 102 4.016 | 350 2.5 | FM UL |

| 150*80 61/2OD*3 | 165.1*88.9 6.500*3.500 | 102 4.016 | 350 2.5 | FM UL |

| 150*100 61/2OD*4 | 165.1*114.3 6.500*4.500 | 102 4.016 | 350 2.5 | FM UL |

| 150*15 6*1/2 | 168.3*21.3 6.625*0.825 | 102 4.016 | 350 2.5 | FM UL |

| 150*20 6*3/4 | 168.3*26.9 6.625*1.050 | 102 4.016 | 350 2.5 | FM UL |

| 150*25 6*1 | 168.3*33.7 6.625*1.315 | 102 4.016 | 350 2.5 | FM UL |

| 150*32 6*11/4 | 168.3*42.4 6.625*1.660 | 102 4.016 | 350 2.5 | FM UL |

| 150*40 6*11/2 | 168.3*48.3 6.625*1.900 | 102 4.016 | 350 2.5 | FM UL |

| 150*50 6*2 | 168.3*60.3 6.625*2.375 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 6*21/2 | 168.3*73.0 6.625*2.875 | 102 4.016 | 350 2.5 | FM UL |

| 150*65 6*3OD | 168.3*76.1 6.625*3.000 | 102 4.016 | 350 2.5 | FM UL |

| 150*80 6*3 | 168.3*88.9 6.625*3.500 | 102 4.016 | 350 2.5 | FM UL |

| 150*100 6*4 | 168.3*114.3 6.625*4.500 | 102 4.016 | 350 2.5 | FM UL |

| 200*25 8*1 | 219.1*33.7 8.625*1.315 | 127 5.000 | 350 2.5 | FM UL |

| 200*32 8*11/4 | 219.1*42.4 8.625*1.660 | 127 5.000 | 350 2.5 | FM UL |

| 200*40 8*11/2 | 219.1*48.3 8.625*1.900 | 127 5.000 | 350 2.5 | FM UL |

| 200*50 8*2 | 219.1*60.3 8.625*2.375 | 127 5.000 | 350 2.5 | FM UL |

| 200*65 8*21/2 | 219.1*73.0 8.625*2.875 | 127 5.000 | 350 2.5 | FM UL |

| 200*65 8*3OD | 219.1*76.1 8.625*3.000 | 127 5.000 | 350 2.5 | FM UL |

| 200*80 8*3 | 219.1*88.9 8.625*3.500 | 127 5.000 | 350 2.5 | FM UL |

| 200*100 8*4 | 219.1*114.3 8.625*4.500 | 127 5.000 | 350 2.5 | FM UL |

- Production Flow

Melting-----Sand Mixing-----Casting-----Shot Blasting&Polishing-----Pressure Testing-----Powder Paiting------Drying&Curing-----Assembling-----Packing

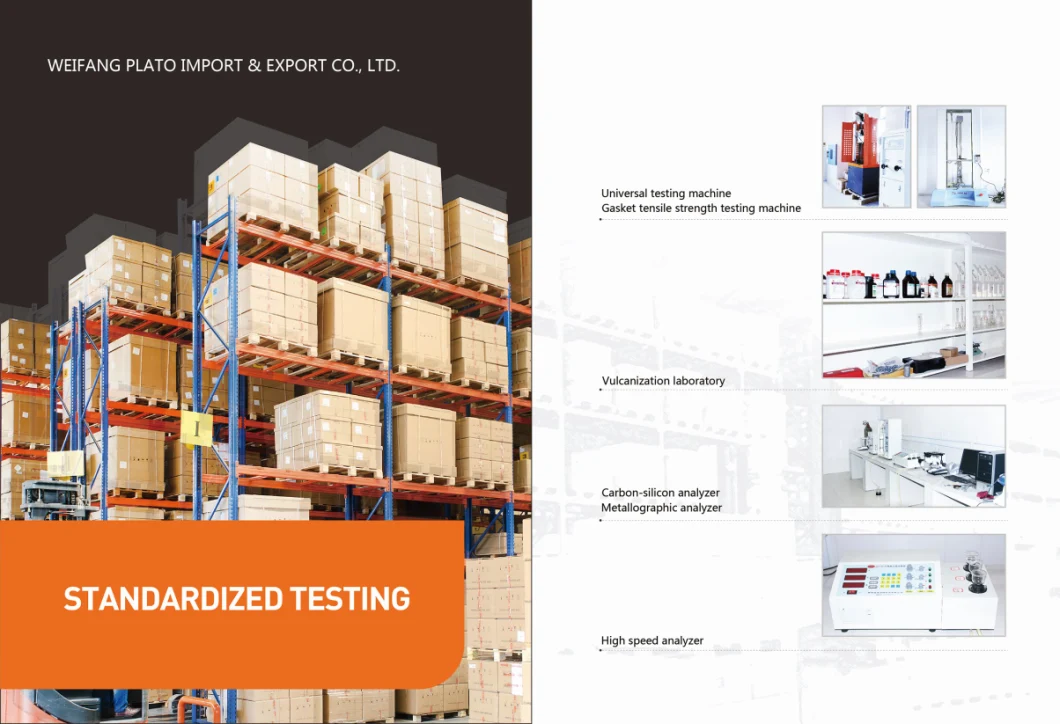

Quality Test

Material Testing-----Gasket Test, Sand Test.

Semi-Finished Products-----Leak Test, Tensile Strength Test, Salt Spray Test, Dimention Inspection, Working Pressure Test.

Finished Products-----Final Visual Inspection.

Our advantages:

1. Most Advanced Production Line

2. Complete Approvals/Certifications

3. OEM and Multi-listing Service

4. Mold Center

5. Professional International Trade Team

Why choose ductile iron pipe fittings ?

Ductile iron pipe production process is in the raw materials of ordinary cast iron pipe added magnesium, calcium and other alkaline earth metal or rare metal casting.

The casting process of ductile iron pipe includes continuous casting, hot mould casting and water cooling centrifugal casting

Compared with ordinary cast iron pipe, it not only maintains the corrosion resistance of ordinary cast iron pipe, but also has the advantages of high strength, good toughness, thin wall, light weight, impact resistance, great bending performance and easy installation.Therefore, ductile iron pipe is not only widely used in foreign countries, but also has been well promoted and used in China.

Comparison of properties between ductile iron pipe and steel pipe:

Compared with ductile iron pipe, steel pipe has the advantages of good toughness, great tensile stre

Performance comparison between ductile iron pipe and PVC plastic pipe:

Compared with ductile iron pipe, the characteristics of PVC pipe is smooth inner wall, light weight, corrosion resistance, anti-fouling performance is good, low price, but also more shortcomings, mainly have the following:

(1) easy to aging, heat expansion and cold contraction, not long-term exposure to sunlight, preservation room temperature should not be greater than 40ºC.

(2) low strength, poor compression performance, improper construction easy to cause deformation...

(3) poor rigidity, poor deflection, easy to cause leakage.

Ductile iron pipe production process is in the raw materials of ordinary cast iron pipe added magnesium, calcium and other alkaline earth metal or rare metal casting.

The casting process of ductile iron pipe includes continuous casting, hot mould casting and water cooling centrifugal casting

Compared with ordinary cast iron pipe, it not only maintains the corrosion resistance of ordinary cast iron pipe, but also has the advantages of high strength, good toughness, thin wall, light weight, impact resistance, great bending performance and easy installation.Therefore, ductile iron pipe is not only widely used in foreign countries, but also has been well promoted and used in China.

Comparison of properties between ductile iron pipe and steel pipe:

Compared with ductile iron pipe, steel pipe has the advantages of good toughness, great tensile stre

Performance comparison between ductile iron pipe and PVC plastic pipe:

Compared with ductile iron pipe, the characteristics of PVC pipe is smooth inner wall, light weight, corrosion resistance, anti-fouling performance is good, low price, but also more shortcomings, mainly have the following:

(1) easy to aging, heat expansion and cold contraction, not long-term exposure to sunlight, preservation room temperature should not be greater than 40ºC.

(2) low strength, poor compression performance, improper construction easy to cause deformation...

(3) poor rigidity, poor deflection, easy to cause leakage.

Weifang Plato Import & Export Co., Ltd. is a comprehensive high-tech enterprise integrating research, development, production& sales as a whole, specializing in the research and development and manufacturing of grooved pipe fittings, with an annual production capacity of more than 1,000,000 tons, is among the best company of china in this industry.

FAQ

Q: Are you trading company or manufacturer ?

A: We are a factory.

Q: How long is your delivery time?

A: Generally 15 days after the down payment. OEM 30 to 90 days.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.