Mechanical properties

a) Tensile strength: ≥420MPa

b) Yield strength: ≥300Mpa

c) Hardness: ≤230HB

d) Elongation%: DN80 - 1000 ≥10 DN1200 - 2200 ≥7

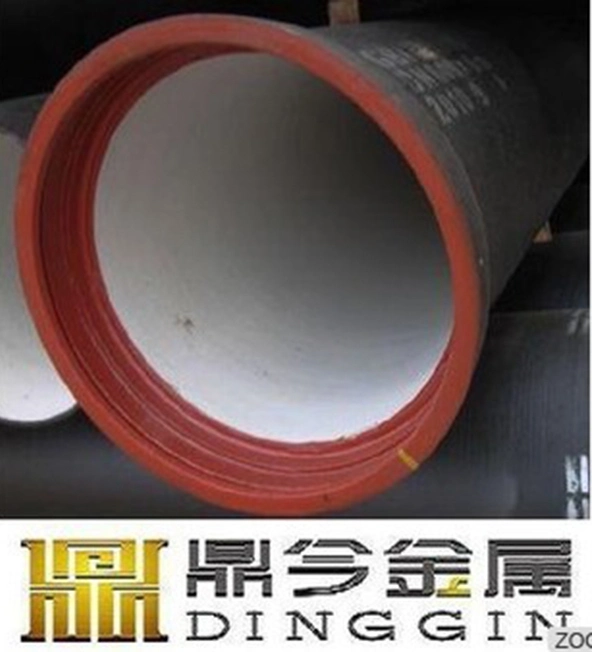

14) The coating of pipes can be

15) Process and testing:

a) Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)

b) Casting (Visual check and weight check)

c) Heat treatment (Micro structure)

d) Hydrostatic test (Pressure test)

e) Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)

f) Zinc spraying (Thickness testing)

g) Lining and coating (100% visual check, thickness testing randomly)

i) Marking and packing (100% visual check)

16) The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc.